In our life, the central hanger of the transmission shaft is generally used for trucks, but not for small cars. The reason is that the distance between the transmission main shaft of small cars and the driving gear shaft of the rear axle reducer is short, and it is connected with a set of transmission shaft assembly. Therefore, the central hanger of the transmission shaft is not set. The distance between the drive shaft and the driven shaft of trucks is relatively long, and the transmission shaft has a connecting part, so the central hanger is used.

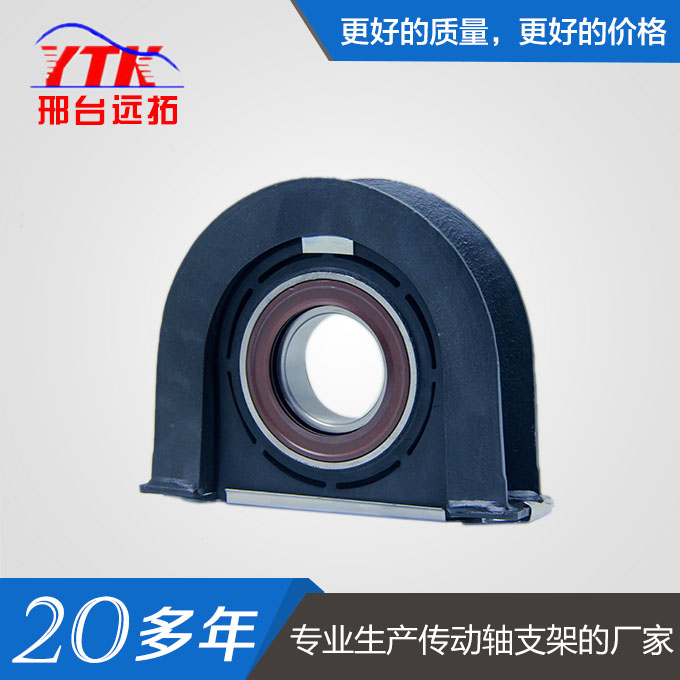

Where is the hanger generally installed? Generally speaking, the central hanger is located in or below the cross beam in the frame. Some hangers are bolted in the cross beam or hoisted under the cross beam. The hanger has two sets of ball bearings and a bearing seat, and rubber rings of different shapes are attached between the periphery of the bearing seat and the hanger seat hole. The rear end of the front drive shaft is positioned by the central hanger, which can ensure the positioning and rotation of the front and rear drive shafts, and the front drive shaft can have micro swing and axial micro displacement. Today, I received a message from a netizen saying that my hanging rubber was broken. I asked Zhanhao if it could be repaired. The answer was yes. Today Zhanhao summarized several damage faults that can easily occur in the transmission shaft hanger.

The damage of the central hanger of the transmission shaft is mainly affected by three aspects.

1、 Affected by damaged hanger bearing. The cause of hanger bearing damage lies in the lack of grease in the bearing, which leads to increased wear and open space. The other is that the outer diameter of the bearing and the seat hole are loose due to long-term failure to overhaul, and the rubber ring around the bearing seat is broken and detached, resulting in the drive shaft bouncing in the hanger, resulting in the fracture of the lower half of the hanger, the fracture of bolts and the fracture of bolt joints.

2、 Affected by damage to transmission shaft components. The damage of transmission shaft components is caused by the deformation of front and rear transmission shaft flange forks, universal joint shaft forks and expansion forks, resulting in axis runout during the operation of the whole transmission shaft, loose wear caused by lack of lubricating grease on the cross shaft, and increased wear between the sliding grooves of the expansion fork. As a result, the air gap of the whole set of transmission shaft increases and axis shimmy occurs during transmission, and the central hanger is affected by its vibration for a long time, resulting in lower part fracture.

3、 Affected by its quality, material and structure. The central hanger of the transmission shaft always maintains the central support of the bearing seat type on the middle crossbeam. The material is cast from malleable cast iron, which is only suitable for trucks with relatively low tonnage. The cast hanger is prone to fracture due to improper technology, loose metal or porosity, brittle material, etc. During maintenance and installation, due to improper bolt fastening method, the hanger or hanger cover was not installed in a balanced and uniform manner, which caused the hanger or hanger cover to be warped and cracked due to pressure concentration, resulting in the hanger breaking.

When the central hanger of the transmission shaft breaks, it will cause the front and rear transmission shafts to be disconnected at the expansion fork, and then the running vehicle will fail. At this time, there is a great potential safety hazard. Therefore, the central hanger of the transmission shaft should also be overhauled regularly to prevent accidents.

Mobile station

WeChat