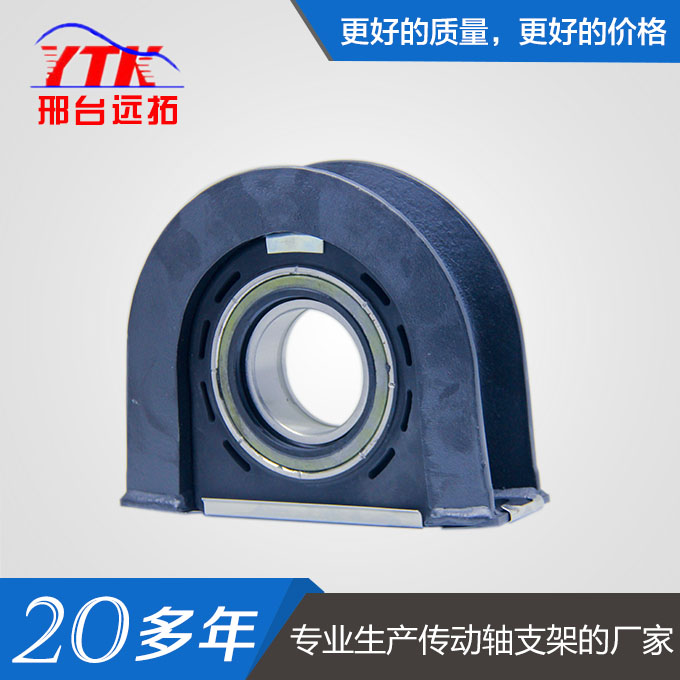

The distance between the driving shaft and the driven shaft of the truck is relatively long, and the transmission shaft has a connecting part, so the central support of the transmission shaft is used. Usually, the center bracket is located in or below the cross beam in the frame. Some of the brackets are bolted in the cross beam or hoisted under the cross beam. The support has two sets of ball bearings and a bearing seat, and rubber ring pads of different shapes are attached between the periphery of the bearing seat and the hole of the support seat. The rear end of the front drive shaft is positioned by the central support, which can ensure the positioning and rotation of the front and rear drive shafts, and the front drive shaft can have micro swing and axial micro displacement.

The damage of the central support of the transmission shaft is affected by the damage of the support bearing, the damage of the transmission shaft components, and the quality, material and structure. After the center support is broken, the front and rear transmission shafts are disconnected at the expansion joints, causing the running vehicle to malfunction.

(1) The cause of hanger bearing damage is the lack of lubricating oil in the bearing, resulting in increased wear or ablation of the bearing and looseness, or loose rotation of the bearing outer diameter and seat hole due to long-term disrepair, rupture or falling off of the rubber ring at the periphery of the bearing seat, etc., resulting in the drive shaft bouncing in the support, resulting in fracture of the lower half of the support, bolt fracture and bolt joint fracture.

(2) The damage of the transmission shaft components is caused by the deformation of the front and rear transmission shafts, cardan shaft forks, joint flanges, and extension and braided joint keyway shafts, resulting in axis runout when the whole transmission shaft is driven; Or the universal joint is excessively worn and loose due to lack of lubricating oil; Or due to the increased wear and looseness between the sliding key groove and the groove of the expansion joint. As a result, the air gap of the whole set of transmission shaft increases and axis shimmy occurs during transmission, and the lower part of the central support is broken due to its shock for a long time.

(3) The center bracket of the transmission shaft of the truck has been kept on the middle crossbeam in the form of bearing block (tile bracket) since the 1940s. The material is made of malleable cast iron (Maanshan Steel). The hanger of this structure is only suitable for trucks with relatively low tonnage (in recent times, some Center brackets of the transmission shaft are made of rolled and welded steel plates, which are sleeved in the middle crossbeam, which is safer). The cast hanger is easy to produce fracture layer due to improper process, loose metal or porosity, brittle material, etc. During the warranty installation of the center support, due to the improper method of fastening bolts, the support or the support cover was not installed evenly and evenly, causing the support or the support cover to be warped and broken due to the concentration of stress at a certain point, thus causing the hanger to break.

As long as there is one of several factors causing the damage of the transmission shaft center bracket, it will cause incalculable losses to the vehicle. Therefore, during the regular maintenance or warranty of the vehicle, the transmission part shall be inspected and adjusted.

Mobile station

WeChat